AGV Castors

High-Performance Industrial Castors for Automated Guided Vehicles

Automated Guided Vehicles (AGVs) run continuously, often 24/7, at higher speeds and loads than manually operated carts. Standard castors wear out quickly under these conditions, increasing the risk of AGV downtime, unplanned... stoppages, and safety issues. Choosing a durable, high-precision AGV castor is essential to maintain productivity, reduce maintenance costs, and ensure reliable navigation.

Our AGV castor range is engineered to deliver exceptional durability, load capacity, swivelling performance, and floor-tracking accuracy across a wide range of AGV applications.

GAPH Series – Compact, High-Durability AGV Castors

Ideal for compact AGVs requiring fast directional changes without sacrificing load performance.

The GAPH AGV castor series is designed for compact AGV environments where space and height are limited. These castors offer:

- Rapid swivelling for precise manoeuvrability

- High load capacity with a low overall height

- Excellent long-term durability

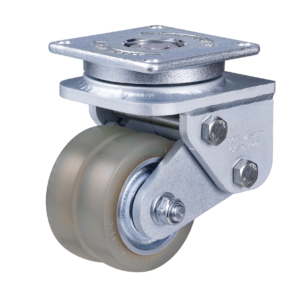

GAGD Series – Twin-Wheel Castors for Heavy Loads

Perfect for high-load AGVs that must maintain precise directional control.

AGVs carrying heavy loads need castors that can change direction smoothly while maintaining accurate line tracking. The GAGD series solves this challenge with:

- Twin wheel (dual-wheel) design for reduced swivel resistance

- Smaller offset to minimise AGV swing and prevent deviation from its guidance line

- Two rows of thrust bearings to increase swivelling performance under very heavy loads

- Reduced strain on AGV drive motors

GASD Series – Shock-Absorbing AGV Castors for Uneven Floors

These castors are ideal for facilities with floor irregularities or older concrete surfaces.

Even floors that appear smooth can have imperfections that cause AGV wheels to lose contact during travel. The GASD series is engineered to maintain stability with:

- 10mm spring-based shock absorption

- Constant wheel-to-floor contact

- Reduced risk of abrupt stops when turning

- Improved AGV stability on uneven surfaces

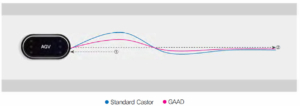

GAAD Series – Automatic Aligning Castors for Optimised Swivel Radius

A powerful solution for AGV engineers seeking better path accuracy and energy performance.

Castor offset plays a major role in AGV navigation. Too large an offset causes line deviation; too small overloads the drive motor. The GAAD series eliminates this problem using:

- Two rotation axes with varying rotation radii

- Patented automatic aligning function

- Dynamic optimisation of the swivel radius

- Reduced AGV swing and improved motor efficiency

In Stock

In Stock100mm AGV Swivel Castor, Twin Wheel, 310kg Load | Polyurethane Wheel, Ball bearing (GAAD100ASFHUD)

This Twin wheel ... Read More100mm Automated Guided Vehicle (AGV) Castor has a bracket made from strong Forged steel that is zinc plated. There is a hardened Taper Roller Bearing in he swivel head, which has a grease nipple, for smooth swivelling action and durability.The castor is unique because it has a self-aligned function enabled by two swivelling axes each with different swivelling radii so that the castor's offset can automatically alter when changing direction to optimise the castor's turning circle for the AGV. Specifically, the offset can range from 10mm to 30mm which reduces the castors 'swing' enabling it to better follow the designated path. The Top Plate is 112mm x 112mm and has 4 bolt holes that are spaced 92mm x 92mm, each with a 9mm hole diameter,This castor frame has two wheels with a Polyurethane tyre (Shore A 95) on an Aluminium centre each containing ball bearings, The polyurethane wheel has excellent elasticity the minimises slipping that can happen when an AGV starts or stops. In addition, the elasticity also absorbs small shocks arising from small imperfections in the floor. The wheel itself is non marking and will not damage the floor.

The Top Plate is 112mm x 112mm and has 4 bolt holes that are spaced 92mm x 92mm, each with a 9mm hole diameter,This castor frame has two wheels with a Polyurethane tyre (Shore A 95) on an Aluminium centre each containing ball bearings, The polyurethane wheel has excellent elasticity the minimises slipping that can happen when an AGV starts or stops. In addition, the elasticity also absorbs small shocks arising from small imperfections in the floor. The wheel itself is non marking and will not damage the floor. £198.56Original price was: £198.56.£192.61Current price is: £192.61.Sale! CompareQty In Stock

In Stock110mm AGV Swivel Castor, 400kg Capacity | 110mm Polyurethane Wheel, Ball bearing (GSAD110ASF)

110mm Automated ... Read MoreGuided Vehicle (AGV) Castor with a dual swivel head fitted with double precision ball bearings to optimise heavy loads. This provides a self-aligning function with two swivelling axes (axis) with different swivelling radii so that the castor aligns on its own according to the moving direction which reduces the turning circle of the castor. The load capacity of this castor is 400kgThe AGV castor comes with twin polyurethane tyre wheels fitted with precision ball bearings which are fitted to a strong welded steel frame that is powder coated with a bolted wheel axle.£866.95Original price was: £866.95.£335.06Current price is: £335.06.Sale! CompareQty In Stock

In Stock125mm AGV Swivel Castor, Twin Wheel, 440kg Load | Polyurethane Wheel, Ball bearing (GAAD125ASFHUD)

This Twin wheel ... Read More125mm Automated Guided Vehicle (AGV) Castor has a bracket made from strong Forged steel that is zinc plated. There is a hardened Taper Roller Bearing in he swivel head, which has a grease nipple, for smooth swivelling action and durability.The castor is unique because it has a self-aligned function enabled by two swivelling axes each with different swivelling radii so that the castor's offset can automatically alter when changing direction to optimise the castor's turning circle for the AGV. Specifically, the offset can range from 15mm to 33mm which reduces the castors 'swing' enabling it to better follow the designated path.The Top Plate is 145mm x 145mm and has 4 bolt holes that are spaced 120mm x 120mm, each with a 11mm hole diameter,This castor frame has two wheels with a Polyurethane tyre (Shore A 95) on an Aluminium centre each containing ball bearings, The polyurethane wheel has excellent elasticity the minimises slipping that can happen when an AGV starts or stops. In addition, the elasticity also absorbs small shocks arising from small imperfections in the floor. The wheel itself is non marking and will not damage the floor.£276.36Original price was: £276.36.£268.07Current price is: £268.07.Sale! CompareQty In Stock

In Stock150mm AGV Swivel Castor, 600kg Capacity | Polyurethane Wheel, Ball bearing (GSAD150ASF)

150mm Automated ... Read MoreGuided Vehicle (AGV) Castor with a dual swivel head fitted with double precision ball bearings to optimise heavy loads. This provides a self-aligning function with two swivelling axes (axis) with different swivelling radii so that the castor aligns on its own according to the moving direction. The load capacity of this castors is 600kg.The AGV castor comes with twin polyurethane tyre wheels fitted with precision ball bearings which are fitted to a strong welded steel frame that is powder coated with a bolted wheel axle.£1,291.78Original price was: £1,291.78.£499.25Current price is: £499.25.Sale! CompareQty In Stock

In Stock150mm AGV Swivel Castor, Twin Wheel, 630kg Load | Polyurethane Wheel, Ball bearing (GAAD150ASFHUD)

This Twin wheel ... Read More150mm Automated Guided Vehicle (AGV) Castor has a bracket made from strong Forged steel that is zinc plated. There is a hardened Taper Roller Bearing in he swivel head, which has a grease nipple, for smooth swivelling action and durability.The castor is unique because it has a self-aligned function enabled by two swivelling axes each with different swivelling radii so that the castor's offset can automatically alter when changing direction to optimise the castor's turning circle for the AGV. Specifically, the offset can range from 15mm to 35mm which reduces the castors 'swing' enabling it to better follow the designated path. The Top Plate is 145mm x 145mm and has 4 bolt holes that are spaced 120mm x 120mm, each with a 11mm hole diameter,This castor frame has two wheels with a Polyurethane tyre (Shore A 95) on an Aluminium centre each containing ball bearings, The polyurethane wheel has excellent elasticity the minimises slipping that can happen when an AGV starts or stops. In addition, the elasticity also absorbs small shocks arising from small imperfections in the floor. The wheel itself is non marking and will not damage the floor.

The Top Plate is 145mm x 145mm and has 4 bolt holes that are spaced 120mm x 120mm, each with a 11mm hole diameter,This castor frame has two wheels with a Polyurethane tyre (Shore A 95) on an Aluminium centre each containing ball bearings, The polyurethane wheel has excellent elasticity the minimises slipping that can happen when an AGV starts or stops. In addition, the elasticity also absorbs small shocks arising from small imperfections in the floor. The wheel itself is non marking and will not damage the floor. £321.19Original price was: £321.19.£311.56Current price is: £311.56.Sale! CompareQty In Stock

In Stock60mm Twin Wheel Swivel Castor | Polyurethane Tyre Wheel, Ball Bearing, 150kg Capacity (GAJSD60ASFHUD)

60mm Swivel Castor with Dual Polyurethane ... Read MoreTyres for AGVsMaximize your AGV’s performance with our high-quality Automated Guided Vehicle Castors. This 70mm swivel castor features dual (twin) polyurethane tyres mounted on durable aluminium centres, complemented by precision ball bearings. Designed to meet the high demands of AGV applications, this castor ensures smooth, efficient, and reliable operation in industrial settings.The black powder-coated bracket offers superior protection compared to standard zinc-plated frames, enhancing durability in harsh environments. Its low overall height of just 87mm makes it ideal for compact AGV systems, ensuring stability without compromising load capacity—supporting up to 150kg (450kg over 4 castors).Key Specifications:

- Top Plate Fixing: 86x61mm bolt hole spacing with 9mm drilled holes, suited for 8mm bolts.

- Dual Polyurethane Tyres: 95 Shore A hardness for low tractive resistance, smooth and quiet operation.

- Non-Marking Tyres: Protects floors and reduces maintenance costs.

- Robust Swivel Bracket: Double ball race swivel head for enhanced manoeuvrability and durability.

Benefits:

- Optimized for AGVs: Engineered for automated guided vehicles, ensuring reliable, continuous performance.

- Smooth, Quiet Operation: Polyurethane tyres reduce rolling resistance and noise, enhancing efficiency.

- Long-Lasting Durability: Strong aluminium centres and black powder-coated brackets for extended lifespan.

£51.19Original price was: £51.19.£49.66Current price is: £49.66.Sale! CompareQty In Stock

In Stock70mm Twin Wheel Swivel Castor | Polyurethane Tyre Wheel, Ball Bearing, 200kg Capacity (GAJSD70ASFHUD)

70mm Swivel Castor with Dual Polyurethane ... Read MoreTyres for AGVsMaximize your AGV’s performance with our high-quality Automated Guided Vehicle Castors. This 70mm swivel castor features dual (twin) polyurethane tyres mounted on durable aluminium centres, complemented by precision ball bearings. Designed to meet the high demands of AGV applications, this castor ensures smooth, efficient, and reliable operation in industrial settings.The black powder-coated bracket offers superior protection compared to standard zinc-plated frames, enhancing durability in harsh environments. Its low overall height of just 97mm makes it ideal for compact AGV systems, ensuring stability without compromising load capacity—supporting up to 200kg per castor (600kg over 4 castors).Key Specifications:

- Top Plate Fixing: 86x61mm bolt hole spacing with 9mm drilled holes, suited for 8mm bolts.

- Dual Polyurethane Tyres: 95 Shore A hardness for low tractive resistance, smooth and quiet operation.

- Non-Marking Tyres: Protects floors and reduces maintenance costs.

- Robust Swivel Bracket: Double ball race swivel head for enhanced manoeuvrability and durability.

Benefits:

- Optimized for AGVs: Engineered for automated guided vehicles, ensuring reliable, continuous performance.

- Smooth, Quiet Operation: Polyurethane tyres reduce rolling resistance and noise, enhancing efficiency.

- Long-Lasting Durability: Strong aluminium centres and black powder-coated brackets for extended lifespan.

£54.15Original price was: £54.15.£52.53Current price is: £52.53.Sale! CompareQty Out of Stock - On the Way

Out of Stock - On the Way75mm AGV Swivel Castor, 100kg Capacity | Polyurethane Wheel, Ball bearing (GAPL75ASFHUD)

75mm Automated G... Read Moreuided Vehicle (AGV) Castor has a bracket made from strong pressed steel with precision ball bearings in the swivel head for smooth swivelling action and durability. The load capacity of this castor is 100kgThe bolt holes are slotted to 78mm x 45mm / 72mm x 45mm with a 9mm hole diameter,This castors is fitted a Polyurethane tyre (Shore A 90) on an Aluminium centre containing ball bearings, The polyurethane wheel has excellent elasticity the minimises slipping that can happen when an AGV starts or stops. In addition, the elasticity also absorbs small shocks arising from small imperfections in the floor. The wheel itself is non marking and will not damage the floor. Many AGV applications require the castor to run 24 hours a day and the durability of the castor is important to reduce costs associated with stoppage. By using bearing steel with a higher strength than general steel in the swivel head, this castor has an exceptional performance.£23.72Original price was: £23.72.£23.01Current price is: £23.01.Sale! Compare In Stock

In Stock75mm AGV Swivel Castor, Dual Wheel, 200kg Capacity | Polyurethane Wheel, Ball bearing (GAPHD75ASFHUD)

Twin wheel 75mm ... Read MoreAutomated Guided Vehicle (AGV) Castor has a bracket made from strong pressed steel with precision ball bearings in the swivel head for smooth swivelling action and durability. This compact castor has a exceptional height to load ratio. The load capacity of this castor is 200kgTwo rows of bearings in the swivel head makes the castor swivel smoothly and the 4 sheets of specially hardened upper and lower bearing seats protects the swivelling parts. This ensures a fast and smooth swivel action for much longer than a standard swivel castor which is important in frequent and continual use.The bolt holes are slotted to 78mm x 78mm / 64mm x 64mm with a 10.5mm fixing bolt hole diameter,This castors is fitted with two wheels with a Polyurethane tyre (Shore A 95) on an Aluminium centre containing ball bearings, The polyurethane wheel has excellent elasticity the minimises slipping that can happen when an AGV starts or stops. In addition, the elasticity also absorbs small shocks arising from small imperfections in the floor. The wheel itself is non marking and will not damage the floor.£58.90Original price was: £58.90.£57.14Current price is: £57.14.Sale! CompareQty In Stock

In Stock75mm AGV Swivel Castor, Twin Wheel, 250kg Capacity | Polyurethane Wheel, Ball bearing (GASD75ASFHUD)

This Twin wheel ... Read More75mm Automated Guided Vehicle (AGV) Castor has a shock absorption function and a bracket made from strong Forged steel that is zinc plated. There is double thrust bearing in the swivel head to achieve a high load capacity and maintain castor performance and durability.The role of the spring in an AGV castor is different to that of a standard shock absorbing castor. In a standard shock absorbing castor, the spring absorbs shock and noise whereas, it's role in a AGV castor is primarily to keep the wheels in contact with the floor.When determining the overall height requirement of a shock absorbing AVG, it should be designed based on the spring cushion being fully compressed.The shock absorbing pad made from a special rubber compound absorbs minor shocks and vibrations to protect the AGV unit. There is a 10mm range of compression which helps prevent the castors from losing contact with the floor which may be caused by small floor imperfections. An AGV's castor leaving the floor when changing directions is often the cause of the AGV becoming unbalanced and coming to a stop by straying off its designated path.The Top Plate is 112mm x 112mm and has 4 bolt holes that are spaced 92mm x 92mm, each with a 9mm hole diameterThis castor frame has two wheels with a Polyurethane tyre (Shore A 95) on an Aluminium centre each containing ball bearings, Having a twin wheel castor is great for reducing the effort required to swivel the castor and most efficient by reducing the amount of room the castor needs to turn the AGV Cart.The polyurethane wheel has excellent elasticity the minimises slipping that can happen when an AGV starts or stops. In addition, the elasticity also absorbs small shocks arising from small imperfections in the floor. The wheel itself is non marking and will not damage the floor.£178.02Original price was: £178.02.£172.68Current price is: £172.68.Sale! CompareQty In Stock

In Stock75mm AGV Swivel Castor, Twin Wheel, 250kg Load | Polyurethane Wheel, Ball bearing (GAAD75ASFHUD)

This Twin wheel ... Read More75mm Automated Guided Vehicle (AGV) Castor has a bracket made from strong Forged steel that is zinc plated. There is a hardened Taper Roller Bearing in he swivel head, which has a grease nipple, for smooth swivelling action and durability.The castor is unique because it has a self-aligned function enabled by two swivelling axes each with different swivelling radii so that the castor's offset can automatically alter when changing direction to optimise the castor's turning circle for the AGV. Specifically, the offset can range from 10mm to 30mm which reduces the castors 'swing' enabling it to better follow the designated path. The Top Plate is 112mm x 112mm and has 4 bolt holes that are spaced 92mm x 92mm, each with a 9mm hole diameter,This castor frame has two wheels with a Polyurethane tyre (Shore A 95) on an Aluminium centre each containing ball bearings, The polyurethane wheel has excellent elasticity the minimises slipping that can happen when an AGV starts or stops. In addition, the elasticity also absorbs small shocks arising from small imperfections in the floor. The wheel itself is non marking and will not damage the floor.

The Top Plate is 112mm x 112mm and has 4 bolt holes that are spaced 92mm x 92mm, each with a 9mm hole diameter,This castor frame has two wheels with a Polyurethane tyre (Shore A 95) on an Aluminium centre each containing ball bearings, The polyurethane wheel has excellent elasticity the minimises slipping that can happen when an AGV starts or stops. In addition, the elasticity also absorbs small shocks arising from small imperfections in the floor. The wheel itself is non marking and will not damage the floor. £178.02Original price was: £178.02.£172.68Current price is: £172.68.Sale! CompareQty In Stock

In Stock75mm AGV Swivel Castor, Twin Wheel, 250kg Load | Polyurethane Wheel, Ball bearing (GATD75ASFHUD)

This Twin wheel ... Read More75mm Automated Guided Vehicle (AGV) Castor has a bracket made from strong Forged steel that is zinc plated. There is a hardened Taper Roller Bearing in he swivel head, which has a grease nipple, for smooth swivelling action and durability. The Top Plate is 112mm x 112mm and has 4 bolt holes that are spaced 92mm x 92mm, each with a 9mm hole diameter.The castor is able to tilt +/- 5o from its central axis according to the flatness of the floor. This ensures that this castor's wheels keep contact with the floor allowing smooth AGV movement and protection of the loaded cargo when changing directions (See illustration below) The wheels are more widely separated from each other than most Twin Wheel Castors. When changing direction, the two wheels spin in opposite directions to each other which reduces the castor offset. The smaller the offset the less chance that the AGV will deviate from its designated line.This castor frame has two wheels with a Polyurethane tyre (Shore A 95) on an Aluminium centre each containing ball bearings, The polyurethane wheel has excellent elasticity the minimises slipping that can happen when an AGV starts or stops. In addition, the elasticity also absorbs small shocks arising from small imperfections in the floor. The wheel itself is non marking and will not damage the floor.

The wheels are more widely separated from each other than most Twin Wheel Castors. When changing direction, the two wheels spin in opposite directions to each other which reduces the castor offset. The smaller the offset the less chance that the AGV will deviate from its designated line.This castor frame has two wheels with a Polyurethane tyre (Shore A 95) on an Aluminium centre each containing ball bearings, The polyurethane wheel has excellent elasticity the minimises slipping that can happen when an AGV starts or stops. In addition, the elasticity also absorbs small shocks arising from small imperfections in the floor. The wheel itself is non marking and will not damage the floor. £178.02Original price was: £178.02.£172.68Current price is: £172.68.Sale! CompareQty In Stock

In Stock125mm AGV Swivel Castor, Twin Wheel, 440kg Capacity | Polyurethane Wheel, Ball bearing (GASD125ASFHUD)

This Twin wheel ... Read MoreAutomated Guided Vehicle (AGV) Castor with 125m diameter wheels has a shock absorbing function and a bracket made from strong Forged steel that is zinc plated. There is double thrust bearing in the swivel head to achieve a high load capacity and maintain castor performance and durability.The role of the spring in an AGV castor is different to that of a standard shock absorbing castor. In a standard shock absorbing castor, the spring absorbs shock and noise whereas, it's role in a AGV castor is primarily to keep the wheels in contact with the floor.When determining the overall height requirement of a shock absorbing AVG, it should be designed based on the spring cushion being fully compressed.The shock absorbing pad made from a special rubber compound absorbs minor shocks and vibrations to protect the AGV unit. There is a 10mm range of compression which helps prevent the castors from losing contact with the floor which may be caused by small floor imperfections. An AGV's castor leaving the floor when changing directions is often the cause of the AGV becoming unbalanced and coming to a stop by straying off its designated path.The Top Plate is 145mm x 145mm and has 4 bolt holes that are spaced 120mm x 120mm, each with a 11mm hole diameterThis castor frame has two wheels with a Polyurethane tyre (Shore A 95) on an Aluminium centre each containing ball bearings, Having a twin wheel castor is great for reducing the effort required to swivel the castor and most efficient by reducing the amount of room the castor needs to turn the AGV Cart.The polyurethane wheel has excellent elasticity the minimises slipping that can happen when an AGV starts or stops. In addition, the elasticity also absorbs small shocks arising from small imperfections in the floor. The wheel itself is non marking and will not damage the floor.£244.22Original price was: £244.22.£236.90Current price is: £236.90.Sale! CompareQty In Stock

In Stock125mm AGV Swivel Castor, Twin Wheel, 440kg Load | Polyurethane Wheel, Ball bearing (GATD125ASFHUD)

This Twin wheel ... Read More125mm Automated Guided Vehicle (AGV) Castor has a bracket made from strong Forged steel that is zinc plated. There is a hardened Taper Roller Bearing in he swivel head, which has a grease nipple, for smooth swivelling action and durability. The Top Plate is 145mm x 145mm and has 4 bolt holes that are spaced 120mm x 120mm, each with a 11mm hole diameter.The castor is able to tilt +/- 5o from its central axis according to the flatness of the floor. This ensures that this castor's wheels keep contact with the floor allowing smooth AGV movement and protection of the loaded cargo when changing directions (See illustration below) The wheels are more widely separated from each other than most Twin Wheel Castors. When changing direction, the two wheels spin in opposite directions to each other which reduces the castor offset. The smaller the offset the less chance that the AGV will deviate from its designated line.This castor frame has two wheels with a Polyurethane tyre (Shore A 95) on an Aluminium centre each containing ball bearings, The polyurethane wheel has excellent elasticity the minimises slipping that can happen when an AGV starts or stops. In addition, the elasticity also absorbs small shocks arising from small imperfections in the floor. The wheel itself is non marking and will not damage the floor.

The wheels are more widely separated from each other than most Twin Wheel Castors. When changing direction, the two wheels spin in opposite directions to each other which reduces the castor offset. The smaller the offset the less chance that the AGV will deviate from its designated line.This castor frame has two wheels with a Polyurethane tyre (Shore A 95) on an Aluminium centre each containing ball bearings, The polyurethane wheel has excellent elasticity the minimises slipping that can happen when an AGV starts or stops. In addition, the elasticity also absorbs small shocks arising from small imperfections in the floor. The wheel itself is non marking and will not damage the floor. £244.22Original price was: £244.22.£236.90Current price is: £236.90.Sale! CompareQty In Stock

In Stock150mm AGV Swivel Castor ,Twin Wheel, 630kg Load | Polyurethane Wheel, Ball bearing (GATD150ASFHUD)

This Twin wheel ... Read More150mm Automated Guided Vehicle (AGV) Castor has a bracket made from strong Forged steel that is zinc plated. There is a hardened Taper Roller Bearing in he swivel head, which has a grease nipple, for smooth swivelling action and durability. The Top Plate is 145mm x 145mm and has 4 bolt holes that are spaced 120mm x 120mm, each with a 11mm hole diameter.The castor is able to tilt +/- 5o from its central axis according to the flatness of the floor. This ensures that this castor's wheels keep contact with the floor allowing smooth AGV movement and protection of the loaded cargo when changing directions (See illustration below) The wheels are more widely separated from each other than most Twin Wheel Castors. When changing direction, the two wheels spin in opposite directions to each other which reduces the castor offset. The smaller the offset the less chance that the AGV will deviate from its designated line.This castor frame has two wheels with a Polyurethane tyre (Shore A 95) on an Aluminium centre each containing ball bearings, The polyurethane wheel has excellent elasticity the minimises slipping that can happen when an AGV starts or stops. In addition, the elasticity also absorbs small shocks arising from small imperfections in the floor. The wheel itself is non marking and will not damage the floor.

The wheels are more widely separated from each other than most Twin Wheel Castors. When changing direction, the two wheels spin in opposite directions to each other which reduces the castor offset. The smaller the offset the less chance that the AGV will deviate from its designated line.This castor frame has two wheels with a Polyurethane tyre (Shore A 95) on an Aluminium centre each containing ball bearings, The polyurethane wheel has excellent elasticity the minimises slipping that can happen when an AGV starts or stops. In addition, the elasticity also absorbs small shocks arising from small imperfections in the floor. The wheel itself is non marking and will not damage the floor. £288.88Original price was: £288.88.£280.22Current price is: £280.22.Sale! CompareQty